Clothing manufacturing process in Dugarco

Have you ever been curious about how your clothes are made, whether they are dazzling dresses or simple shirts? The clothing manufacturing process is not as simple as just sewing together some fabric pieces. It involves many steps and skills, from design to delivery. In this article, Dugarco will show you the basics of how garments are produced.

>>>> CLICK HERE: Vietnam clothing manufacturers | High quality and reputable products

1. Summary of steps in the clothing manufacturing process

The manufacturing process for clothing is never fixed. Here are 5 basic steps of manufacturing process that most of the process of making all clothes must go through.

1.1 Pre-production stage

This stage is important in the clothing manufacturing process as it contributes to a more complete and quality product. This stage involves two essential steps of manufacturing process including “Fabric and Trim Sourcing” and “Pattern Making”.

1.1.1 Fabric and trim sourcing

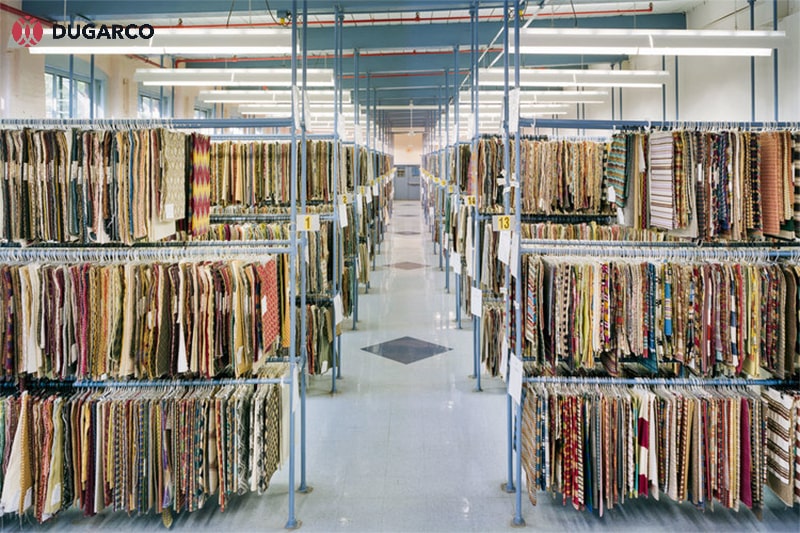

In the steps in manufacturing process, after the final design was completed, manufacturers began to turn to experienced professionals for advice on choosing the right fabric. They can then start producing fabrics in their own company or buy from reputable partners. Once they have the fabric, they can inspect its quality and use it for production if it passes the standard. After the fabric is selected, it will be taken to the cutting area. The fabrics are aligned manually or mechanically to become uniform plies.

>>>> SUGGEST: Choosing women’s clothing manufacturer with superior standards

1.1.2 Pattern Making

The pattern-making process is very important in the clothing manufacturing process because it greatly affects the quality of the final product. This production process steps can be applied to either flat paper or flat fabric. Often the manufacturing process of clothes on flat paper is more common. This is because it is easier to take off the pattern from the paper. The type of paper they usually use is called pattern paper. Using modern techniques, they break down designs into 2D pieces and then create different individual pieces of clothing.

1.2 Production planning

The manufacturing process for clothing must be scientifically organized for everything to go in the right direction, closely, efficiently, and on time. Everyone understands what to do and when to do every step in the manufacturing process steps once the strategy is in place. A great plan also makes it easier to reach the project’s targets. Furthermore, when planning, manufacturers anticipate some risks to deal with them more flexibly in the future.

To ensure quality in the clothing manufacturing process, careful grading is essential. Grading is the manufacturing process steps in a range of sizes for a single garment type. Grading is used to correctly fit a design to a range of sizes. Grading just increases or decreases the size of the previous shape. When you have your pattern and your fit for a middle-sized size is accepted, the pattern is “graded” for the size range you choose.

>>>> DO NOT MISS:

- 10+ Most sustainable and men’s eco friendly clothing brands

- 12 types of sustainable fabric & material for eco-friendly clothing

1.3 Cutting process

An effective cutting process is crucial for optimizing the company’s fabric resources. The fabric-cutting process demands high accuracy. If the fabric is cut wrongly, it is hard to fix it, and a small mistake in the cutting process can affect the production time and result. There are cutting technologies that are very advanced such as laser-cutting and heat that can help to avoid mistakes and save fabrics when cutting them.

>>>> WATCH NOW:

- Eco friendly clothing manufacturers are sustainable trendy cheap

- Best outdoor clothing manufacturers and wholesalers 2024

1.4 Manufacturing and quality control

A thorough inspection action is needed by the manufacturer to make sure that the product quality satisfies the client’s requirements. The quality check manufacturing process of clothes usually starts from the garment production to monitor everything and detect errors. This way, they can be corrected timely in the clothing manufacturing process. After the products are completed, businesses also need to check again on quality as well as quantity to minimize the situation of returning goods from clients. There are several ways to make the quality control manufacturing process steps most effective:

- We are creating a standard to serve as a criterion for evaluating quality performance.

- The output of the steps in manufacturing process can be measured and compared to the planned quality standard.

- If there are any deviations from the plans, corrective actions must be taken.

A thorough examination of each step in the manufacturing process for clothing helps you anticipate possible risks. This would result in higher production efficiency.

>>>> READ NOW:

- How much does it cost to produce clothing from Asia factories?

- OEM clothing manufacturer Vietnam: Pros and cons

1.5 Shipping

At the end of the clothing manufacturing process, after being thoroughly inspected, the products will be neatly folded, labeled, sized, and packaged according to the customer’s specifications. Other hanging clothing, such as coats, dresses, and skirts, are typically bagged by manual, semi-automatic, or completely automatic equipment. Another step is to pack the clothing in protective plastic bags, so that the material stays neat and tidy during shipping. Then, the items are put in cardboard boxes and sent to client distribution centers before reaching the retail stores.

>>>> LEARN MORE: Quality control clothing – The importance and procedures

2. How to reduce time in the clothing production process

Here are some things to note when applying lean manufacturing principles that you need to know:

- Identify and eliminate non-value-added activities during production, which can range from unnecessary steps in the production process to excessive packaging.

- Continuously update and improve production processes to ensure that lean production is effective and sustainable in the long term.

- Focus on streamlining the production process such as implementing lean techniques, machinery or tools.

- With advice on lean production, your business will be optimized and reduce waste in the garment process.

3. Experience to improve the clothing manufacturing process

There are a few things you can do to reduce time and optimize your clothes production process. Here are a handful of our recommendations:

- Improving your management of supply chains is one option. This involves making certain that your suppliers can meet their delivery deadlines and that you have adequate stock levels.

- Streamlining your operations is another technique to reduce time to market in garment production. This could entail implementing lean inventory principles or employing just-in-time management of inventory techniques.

- You should always stay connected with your supplier or retailer during the manufacturing process. Maintaining this relationship will help you get valuable feedback, thereby improving your processes, and ensuring the best quality for your products.

- The clothing manufacturing process does not need to be too complicated. You need to keep the manufacturing process steps as simple as possible to ensure the garment is manufactured to standards and to reduce the risk of manufacturing errors.

- Consult experts: If you still have concerns about something or don’t know where to start, consult and trust expert opinions. They will guide you through the process and ensure your garments are up to industry standards.

4. Distributor of quality clothing and apparel products in Vietnam

Since its beginning in 1990, Dugarco has been a key player in the Vietnam textile and garment industry. Dugarco is proud of its ability to meet the demand for extraordinarily large quantities of items. To have this capacity, the business owns 25 workshops, 165 manufacturing lines, and more than 8000 employees. The corporation has clients and partners all around the world, both domestic and international. Many well-known companies, like Calvin Klein, JCPenney, Costco, Nautica, and others, have placed their trust in the company and collaborated with Dugarco, bolstering the company’s standing.

Dugarco always puts product quality first. Dugarco uses organic cotton and recycled polyester as the main materials for its products. These materials are eco-friendly and make clients feel more connected to the products. Dugarco produces each product line, from jackets to pants, with the utmost care and attention to detail. However, with full of experience and smart strategies, Dugarco is confident to give you quality products at a reasonable price.

>>>> READ NOW: Vietnam shirt manufacturers prestige, cheap, popular

All steps in the manufacturing process are meticulously performed under strict supervision. Everything is carefully planned and there are risk management plans in place in case any problems arise. Therefore, the clothing manufacturing process at Dugarco always ensures high quality and efficiency. With many years of experience, Dugarco always takes the right steps in its working process. Some outstanding strengths can be mentioned:

- High product quality: All products are examined by a third-party inspection organization. The quality defect rate is less than 1% once the garment is delivered to the customer

- On-time delivery: In 2019, 98% of orders were delivered on time. Up to now, no customer has returned due to late delivery.

- Advanced manufacturing technology: Dugarco always focuses on investing in the most advanced equipment to improve production efficiency. In particular, the company is expertise in designing unique down jacket pattern

- Professional in material sourcing: With a large network of partners, Dugarco can find a variety of fabrics from the most reputable sources.

- High value of production in Vietnam: Dugarco is a prominent enterprise in Vietnam, where there is an abundant labor force, and a large labor market, bringing many benefits to the production and distribution of products. Besides, the policies of the Vietnamese government are also very attractive for the development of corporations.

Some frequently asked questions

How to find clothing manufacturers for your business ?

Online directories are a prime resource for finding manufacturers. Directories contain extensive listings of thousands of manufacturers, suppliers, and wholesalers. An example of an online directory is Maker’s Row, a platform that facilitates the manufacturing process by providing clear and accessible information.

Difference between FOB and CIF in the apparel industry

Under the FOB shipping agreement, the buyer assumes all risks of loss or damage to the goods. Conversely, in the case of CIF shipment, the seller bears the responsibility for covering any expenses related to damaged, broken, or misplaced items.

Are textile labeling requirements mandatory?

Labeling requirements are absolutely essential and must be adhered to without exception. Failure to include the required information and graphics on imported or manufactured apparel renders the product illegal and ineligible for sale in the market.

In this article, Dugarco has taken you through each step of the clothing manufacturing process. You will feel amazing because behind those simple clothes is a powerful team that gradually perfects it through many stages. After having a better understanding of the clothing production process, hope that you can come up with more accurate criteria for choosing your manufacturer. We believe you find this information useful and interesting. If you have any questions or feedback, feel free to contact us.

>>>> RELATED ARTICLES: A prestigious fashion design studio in Vietnam, a good price

Dugarco under the talented leadership and guidance of Mr. Hoang Ve Dung has gradually become a large Vietnam clothing manufacturer, supplying clothes for many famous brands from many different countries such as the UK, USA, and Australia.

9 Responses

Dear Sir

I Need a supplier or Individuals who can Participate to ongoing contract to supply any of this items :

1.T-shirt

2.Towels,

3.Hat caps

4.Medical Glove

5.Disposable Isolation Gowns

6.Medical Face Masks

7.Medical Infrared Thermometer

8.ppe

9.Medical Product

10.Drilling Pipes

11.T-shirt Bag

12.industrial machine

To my Organization for Bidding Project.

Thanks

mr muhammad Dear Sir

I Need a supplier or Individuals who can Participate to ongoing contract to supply any of this items :

1.T-shirt

2.Towels,

3.Hat caps

4.Medical Glove

5.Disposable Isolation Gowns

6.Medical Face Masks

7.Medical Infrared Thermometer

8.ppe

9.Medical Product

10.Drilling Pipes

11.T-shirt Bag

12.industrial machine

To my Organization for Bidding Project.

Thanks

mr muhammad

What are some of the challenges of the clothing manufacturing process?

Some of the challenges of the clothing manufacturing process include:

Quality control: It can be difficult to ensure that all of the garments produced meet the required quality standards.

Efficiency: Manufacturers need to be efficient in order to produce garments at a competitive price.

Sustainability: Manufacturers need to be mindful of the environmental impact of their operations.

What are some of the ways that the clothing manufacturing process can be made more sustainable?

There are a number of ways that the clothing manufacturing process can be made more sustainable. For example, manufacturers can use sustainable materials, such as organic cotton and recycled polyester. They can also reduce their energy consumption and water usage.

Hi, can I ask about your supply chain in my project at university? Thank you

What is the process of cotton garment manufacturing?

The process of cotton garment manufacturing involves several stages, from cultivating cotton plants to producing finished garments. Here is a general overview of the key steps in the process: Cotton Cultivation -> ginning -> spinning -> weaving or knitting -> dyeing and finishing -> cutting -> sewing -> quality control -> finishing and pressing -> packaging and distribution

What are the main raw materials for making clothes?