In response to the growing trend of using recycled and ecologically friendly materials, econyl fabric was created as the ideal that offers the fashion industry a number of advantages. In this article, Dugarco will discuss this material in this article, as well as its benefits and drawbacks in order to assist you make a well-informed choice about utilizing this sustainable material in your lifestyle.

>>>> CLICK NOW: 15 Eco friendly clothing materials for fashion sustainable

1. What Is Econyl Fabric?

Due to the fact that econyl fabric is a relatively new and recently developed material, maybe a lot of people are still unfamiliar with it. However, by employing recycled foundation materials, econyl, a famous nylon alternative manufactured from waste products, significantly lowers the amount of non-biodegradable trash that is disposed of.

1.1. The history of Econyl and Nylon

Nylon was invented for the first time in the 1930s by an American corporation. Nylon is flexibility, durability, as well as extra-low price, helped its fame swiftly spread across the textile industry. However, these materials pose great concerns to the environment because of their non-biodegradability.

In response to these environmental worries, econyl was first developed in 2011. Econyl is a form of regenerated nylon fabric made from waste nylon materials, which is broken down and reconstituted into new material. They offer several benefits in terms of durability, breathability, and aesthetics. Hence, they are commonly used in the modern fashion industry.

>>>> DON’T MISS OUT: Top 5 the best Vietnam clothing manufacturers prestige 2024

1.2. The attributes of Econyl fabric

Econyl has all the characteristics of regular nylon cloth since it is chemically similar to nylon. Its durability and simple weaving ability help it create tightly-knit garments and industrial textiles. However, this fiber is not elastic in its unprocessed state, so it must be woven into fabric in order to become stretchy.

2. How is Econyl material made and used?

Econyl is created from recycled resources, mostly used fishing nets and other nylon trash. To create the ultimate product, they must go through several challenging procedures:

- Depolymerization: Existing nylon polymer is broken down into the monomer state using chemical methods.

- Rendering: The recycled nylon’s components are reduced to a molten polymer state.

- Extrusion: After that, this substance is extruded through a metal spinneret.

- Loading: Then it is wound onto a bobbin, a particular kind of spindle.

- Stretching: Then, these fibers are stretched to improve their flexibility and strength.

- Drawing: They are then wound onto another spool

- Spinning: The econyl fibers may be spun into yarn, chemically processed, and colored.

- Weaving: Econyl fibers finally are prepared to be weaved into consumer clothing.

Econyl fabric is a flexible textile that may be applied in a variety of situations. Using econyl material can be observed in the following ways:

- Apparel: The smooth and comfortable feel of econyl makes it ideal for use in clothes meant to be worn adjacent to the skin, such as t-shirts, dresses, and other kinds of clothing.

- Industrial applications: Additionally, the econyl material offers industrial utilizes. It is a sturdy and long-lasting fabric that can tolerate extensive use and is unaffected by UV radiation, chlorine, and other unfavorable environmental factors, thus can be used to make carpeting and upholstery.

- Sportswear: Due to its low weight, breathability, and moisture-wicking properties, econyl is a popular material for sportswear. Swimwear, cycling jerseys, and running shorts are some examples of apparel made specifically for outdoor activities or athletic pursuits that benefit from its moisture-wicking and quick-drying qualities.

3. Where is Econyl fabric made?

Econyl fabric is produced by Aquafil, an Italian business that specializes in the manufacturing of environmentally friendly nylon products. Where it is now produced by Aquafil has not been made public. It is likely that econyl is made in any one of the company’s several sites located across Italy and abroad, including those in Slovenia, Croatia, and the United States.

4. What is the cost of Econyl raw material?

Currently, there is no information available about econyl’s current price. In general, because econyl is created from recycled materials and has a smaller environmental effect than typical nylon materials, it is more affordable than those materials. Even though the cost of econyl raw materials may be slightly more than some traditional materials, the advantages of utilizing a sustainable and eco-friendly material like econyl can make it a wise choice for businesses and customers.

>>>> YOU MAY NOT KNOW:

- What is deadstock fabric? A guide to sustainable fashion

- Everything you need to know about rayon fabric sustainable

- Is Nylon Fabric biodegradable and eco friendly?

5. Different types of Econyl fabric

Econyl fabric is currently widely utilized in the fashion business, although few people are aware that it comes in a variety of distinct varieties. Here are the two most common econyl material kinds.

5.1. Econyl Textile Fiber

A form of econyl fabric called econyl textile fiber is intended for usage in apparel and accessories. Due to its softness and comfort, this material is frequently used for athletics, swimwear, and other types of clothing. In addition, econyl textile fibre is robust and unaffected by chlorine, ultraviolet radiation, and other abrasive environmental elements.

5.2. Econyl Carpet Fiber

Another type of econyl called econyl carpet fiber is intended for use in carpets and other flooring applications. Strong and resilient, this fabric can resist wear and tear from intense foot activity. Additionally, econyl carpet fiber has good stain and fade resistance.

6. The pros and cons of Econyl material

Econyl material has grown in popularity as a more environmentally friendly substitute for conventional nylon textiles. While it provides a number of benefits over conventional nylon, there are some possible disadvantages as well that should be taken into account.

6.1. Pros of Econyl material

- In the long term, utilizing econyl material might be less expensive than using conventional nylon textiles since it offers higher functionality and durability.

- Econyl is a material renowned for its sturdiness and longevity. It is resistant to exposure to chlorine, UV radiation, and other severe environmental elements.

- The smooth and silky texture of econyl feels great on the skin.

6.2. Cons of Econyl material

- Econyl fabric is highly flammable and has poor thermal stability.

- Econyl is not biodegradable.

- Due to the expense of gathering and processing recycled resources, econyl is often more costly than many other materials like cotton.

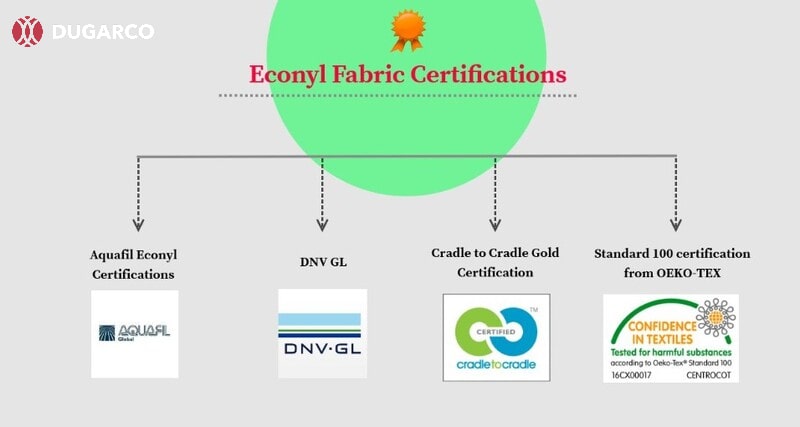

7. Certifications for Econyl fabric

DNV GL, an Italian government agency in charge of product certifications, has granted econyl its accreditation. Desso, a well-known carpet manufacturer, has also awarded “Cradle to Cradle Gold” accreditation to Aquafil’s carpet-grade Econyl. OEKO-TEX has also granted econyl its “Standard 100” certification.

8. How to Care for Econyl Fabric

Although econyl fabric is a high-quality and resilient material, it still has to be properly cared for and maintained in order to last as long as possible. Here are some pointers for maintaining econyl clothing:

- Your econyl product should be washed separately at a cold or low setting with ordinary washing detergent. In order to limit the harm chlorine bleach may do to the quality of your garments, you must also avoid it at all costs.

- For maximum durability, air drying your econyl clothing is recommended, especially for delicate items like underwear and stockings. To prevent any potential harm, you should also use the lowest temperature while operating a dryer machine.

9. The environmental impact of Econyl cloth

Econyl’s benefits for the environment are still debatable. While it is obvious that this regenerated nylon fabric has a lower environmental effect than conventional nylon, it still does not address all the problems caused by this highly polluting fabric.

9.1. Production

Waste that would normally take decades or centuries to decompose is converted into the usable fabric during the creation of econyl fabric. By using this method, nylon items are kept out of the garbage and the seas. However, econyl is regularly coloured, much like nylon, and the majority of clothing dyes are poisonous and bad for both people and the environment.

9.2. Biodegradability

Econyl is not biodegradable, like all other textiles made from fossil fuels. Similar to nylon, discarded econyl textiles accumulate in terrestrial and aquatic habitats, adding to the microfibre catastrophe that is quickly lowering the quality of the world’s water.

9.3. Toxicity

The process of making econyl is quite potentially dangerous. Although it is feasible to create econyl without harming employees, the majority of nylon is produced in third-world nations where there are few laws protecting employees

9.4. The Bottom Line

The manufacturing of econyl material aids in the recovery of nylon waste, the transformation of that waste into nylon fiber, the creation of textile products, and the recycling of those textile products. However, although being fundamentally very advantageous, the overall environmental advantages of this cloth will not materialize until econyl manufacturing surpasses that of modern nylon.

>>>> FIND OUT MORE: Organic Wool: How it benefits you and the environment

10. Is Econyl stuff sustainable and can it completely replace Nylon?

Econyl was first invented to replace virgin nylon, and it is now capable of doing so entirely. Econyl shares the same characteristics as nylon since it is a kind of recycled nylon. However, it is far more environmentally friendly and can be produced from already existing nylon waste without the need for fossil fuels.

11. Best alternatives to Econyl fabric

Despite being a sustainable and environmentally friendly material, econyl fabric might not be the ideal choice for everyone. Here are some substitute materials with comparable advantages:

- Recycled Polyester: Recycled polyester popularly known as rPET, is manufactured from recycled single-use plastic bottles, textile waste, plastic bags, and other materials. It is a popular choice among many well-known sustainable manufacturers and is a rather adaptable fabric. Despite sharing many of polyester’s characteristics, recycled polyester uses around 60% less energy in manufacture than virgin polyester.

- Modal: Modal is a semi-synthetic sustainable fabric that is made from cellulose extracted from beech trees. It is a type of viscose rayon that is durable and offers all the properties of an ideal fabric like strength, comfort, softness, and breathability.

- EcoVero: EcoVero is a semi-synthetic material manufactured from sustainable wood. It is a kind of viscose fiber that uses significantly less water than is required to produce viscose and generates 50% less carbon emissions. Wearers can enjoy the soft, comfortable, and opulent feel of EcoVero fabric items of clothing.

12. Comparison between Econyl, cotton and polyester

Three common substances used in the textile industry are cotton, polyester, and econyl. Here is a comparison of these materials:

| Characteristics | Econyl | Cotton | Polyester |

| Softness | Not as soft as cotton. | It feels rough at first, but after usage and cleaning, it becomes softer. | It is a little coarse, so sensitive skin might not be suitable. |

| Breathability |

|

|

|

| Durability | Super long-lasting and durable | Although durable, it needs more washings than other materials. | Super long-lasting and durable |

| Maintenance | Easy to care for and machine-washable | Easy to care for and machine-washable | It is machine washable and doesn’t need any special care. |

| Resistance to wrinkles | Yes | No | Yes |

| Price | Cheaper than other fabrics | Equal with other fabrics | Cheaper than other fabrics |

Businesses and customers can join hands to protect the environment while still getting the advantages of a long-lasting, high-quality material by choosing econyl fabric items of clothing. Dugarco hopes this post can provide you with additional relevant information. Do not hesitate to contact us if you have any questions!

Contact information:

- Address: 59 Đức Giang, Đức Giang, Long Biên, HN

- Phone: 024 3655 7930

- Email: dugarco@mayducgiang.com.vn

- Website: https://dugarco.com/en/

>>>> RELATED POSTS:

- Is Tencel fabric sustainability and good for the environment?

- Modal fabric: A sustainable and eco-friendly made from cellulose

Dugarco under the talented leadership and guidance of Mr. Hoang Ve Dung has gradually become a large Vietnam clothing manufacturer, supplying clothes for many famous brands from many different countries such as the UK, USA, and Australia.