Choosing the right nhà sản xuất quần áo nữ is a critical decision for fashion brands looking to balance quality, scalability, ethics, and cost efficiency. In this article, Dugarco explores leading women’s clothing manufacturers, highlights their core strengths and weaknesses, and breaks down the standard women’s clothing manufacturing process to help brands identify the best production partner for their specific needs.

1. The Lefty Production Co. – One of the best women’s clothing manufacturer

Lefty Production Co. is a one-stop shop for design, development, and production, supporting designers and brands from concept to final product. As a trusted women’s clothing manufacturer, Lefty works with both emerging and established fashion labels, delivering high-quality apparel through a collaborative and transparent production process. With a strong commitment to domestic manufacturing, Lefty is recognised as a reliable women’s clothing manufacturer in USA serving a diverse range of clients.

Lefty provides end-to-end apparel production services, including design development, sampling, sourcing, and full-scale manufacturing. The company specialises in women’s fashion, accessories, and performance wear, with experience producing collections in the USA, Asia, and South America.

Its portfolio includes collaborations with high-fashion designers such as Matthew Williamson, Rosetta Getty, and Christian Siriano, as well as major retailers like Nordstrom and Neiman Marcus. Lefty has also delivered official uniforms and merchandise for global television productions and entertainment brands.

Strengths

- One-stop shop capability: Seamless integration from design to production.

- Extensive industry expertise: Decades of hands-on experience across global manufacturing markets.

- Strong reputation and client portfolio: Proven work with leading designers, retailers, and media brands.

- Made in the USA focus: Commitment to quality, ethical standards, and domestic production.

- Community engagement: Active supporter of fashion education and emerging talent.

Weaknesses

- Higher production costs compared to fully offshore manufacturers due to USA-based operations.

- Limited suitability for ultra-high-volume orders, as the company prioritises quality and flexibility.

- Primary focus on women’s apparel, which may limit diversification into other product categories

2. ARGYLE Haus of Apparel

ARGYLE Haus of Apparel is a Los Angeles–based fashion design house and apparel manufacturing company serving startups, emerging designers, growth-stage businesses, and national brands. As a full-service women’s clothing manufacturer, ARGYLE Haus delivers end-to-end solutions that help brands transform creative ideas into high-quality, market-ready products. With a strong commitment to domestic production, the company is widely recognised as a trusted women’s clothing manufacturer in USA, known for ethical practices, innovation, and operational excellence.

ARGYLE Haus offers fully integrated fashion services, including technical design, pattern making, product development, sampling, and Made-in-USA apparel manufacturing. By owning its factory, equipment, and production processes, the company maintains complete control over quality, timelines, and costs. Its core focus lies in women’s apparel, lifestyle fashion, and intimate wear, providing scalable solutions that support brands from initial launch through national expansion.

Strengths

- True one-stop-shop model with all services handled in-house, reducing fragmentation and production risk.

- Extensive industry expertise, backed by over 150 years of combined experience across fashion, manufacturing, and business strategy.

- Strong leadership and vision, driven by an experienced founder with a proven track record in brand building and global manufacturing.

- Made-in-USA manufacturing, ensuring high quality, ethical standards, and supply chain transparency.

- Startup- and growth-focused approach, offering strategic guidance beyond production alone.

Weaknesses

- Higher production costs compared to overseas manufacturers due to domestic labour and compliance standards.

- Limited cost competitiveness for ultra-low-budget brands, particularly those focused solely on price-sensitive mass markets.

- Primary concentration on women’s apparel, which may restrict diversification into broader apparel categories.

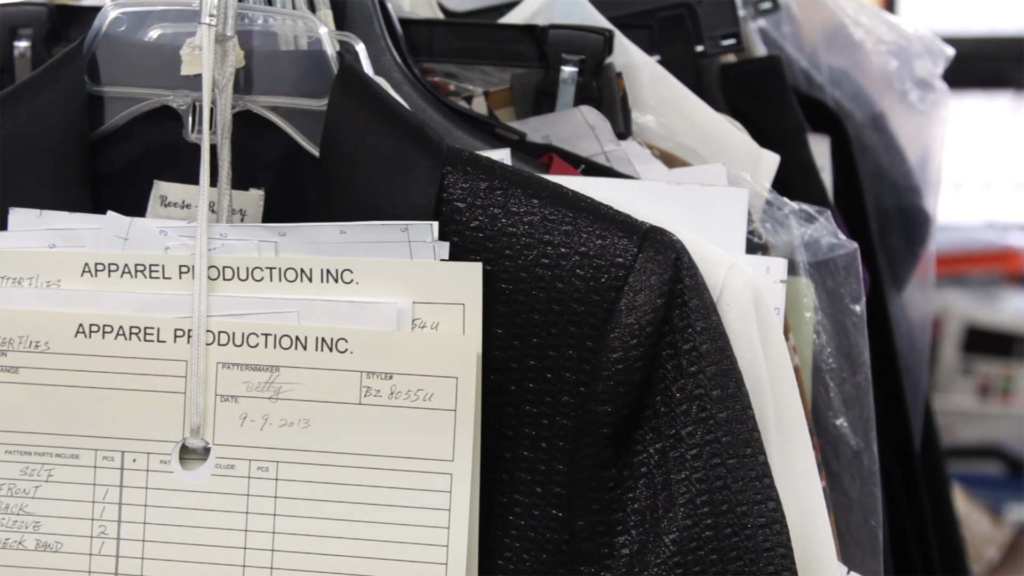

3. Apparel Production Inc

Apparel Production is a family-owned clothing manufacturing facility and design studio based in New York City’s historic Garment District. Established in 1947, the company has over 75 years of experience serving local and global fashion brands. As a trusted women’s clothing manufacturer, Apparel Production is known for its craftsmanship, consistent fit, and long-standing commitment to quality. With domestic and international production capabilities, the company is widely recognised as a reliable Women’s clothing manufacturer in USA.

Apparel Production provides end-to-end apparel manufacturing services, including design development, sampling, fitting, private label production, and large-scale manufacturing. All garments are developed and sampled in the NYC studio, ensuring precise fit and quality control. The company produces men’s, women’s, and children’s apparel, with flexible options for both domestic and overseas manufacturing to meet diverse cost, volume, and timeline requirements.

Strengths

- Long-established industry reputation with over seven decades of manufacturing excellence.

- Family-owned leadership offering hands-on involvement and deep industry knowledge.

- Strong presence in NYC’s Garment District, providing direct access to skilled talent and resources.

- Flexible production model, supporting both domestic and international manufacturing.

- Comprehensive quality control system with dedicated domestic and offshore teams.

Weaknesses

- Higher domestic production costs compared to fully offshore manufacturers.

- Traditional manufacturing focus, which may limit appeal to brands seeking highly experimental or tech-driven production methods.

- Capacity constraints for extremely large-volume orders, particularly when prioritising U.S.-based production.

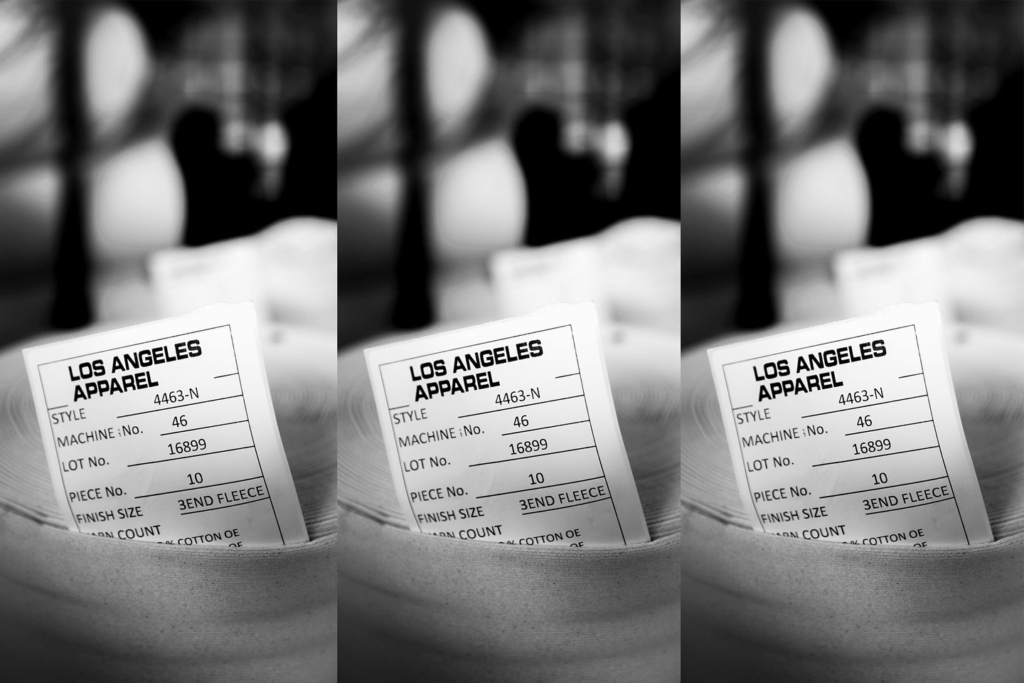

4. Los Angeles Apparel

Based in Los Angeles, Los Angeles Apparel is a vertically integrated apparel manufacturer driven by a contrarian approach to sustainability, efficiency, and ethical production. As a socially responsible women’s clothing manufacturer, the business is committed to reshaping the garment industry by prioritising fair wages, local job creation, and environmentally responsible practices. With all production kept domestic, the company stands out as a fully transparent women’s clothing manufacturer in USA, focused on long-term value rather than fast fashion.

Los Angeles Apparel specialises in the design and manufacturing of high-quality wardrobe essentials and premium basics. Services include in-house product development, fabric sourcing, dyeing, cutting, sewing, and finishing, all handled under one roof in Los Angeles. By supporting U.S. farmers and domestic yarn suppliers, the company ensures supply chain integrity while delivering durable, sustainable garments designed for everyday wear.

Strengths

- Fully vertically integrated manufacturing, ensuring strict quality control and consistency.

- Ethical labour practices, with fair wages and safe working conditions.

- Strong commitment to sustainability, including recycled materials and near-zero manufacturing waste.

- 100% Made in the USA production, reducing supply chain risk and carbon footprint.

- Highly skilled, long-tenured workforce, blending traditional craftsmanship with modern technology.

Weaknesses

- Higher production costs compared to offshore manufacturing due to domestic labour and environmental standards.

- Limited price competitiveness for brands targeting low-cost or fast-fashion segments.

- Scalability challenges when responding to sudden large-volume demand while maintaining ethical standards.

5. Bryden Apparel

Bryden was founded in 2013 to support independent fashion brands, e-commerce retailers, and established companies with end-to-end sourcing and apparel production solutions. Positioned as a global supply chain partner, Bryden operates with a partnership-driven mindset, helping creative ideas turn into commercial-ready products. As a flexible women’s clothing manufacturer, the company works with clients worldwide and supports both emerging and growth-stage fashion labels. Bryden also collaborates with U.S.-based partners, positioning itself as a capable women’s clothing manufacturer in USA for brands seeking access to the American market.

Bryden manages the entire apparel supply chain, including design and development, fabric and trim sourcing, sampling, bulk production, packaging, quality control, and logistics coordination. The company specialises in women’s apparel and private label production, enabling brands to launch and scale efficiently while focusing on sales and marketing rather than operational complexity.

Strengths

- End-to-end supply chain management, simplifying apparel manufacturing for brands.

- Founder-led industry expertise, combining fashion, e-commerce, and operational experience.

- Design-driven and process-oriented culture, ensuring efficiency and consistency.

- Global client reach, with experience working across multiple international markets.

- Strong partnership mindset, treating each project as a long-term collaboration.

Weaknesses

- Limited direct manufacturing ownership, relying on partner factories for production.

- Quality consistency dependency on external suppliers and production partners.

- Less suitable for brands seeking fully in-house or Made-in-USA-only manufacturing.

6. Women’s Clothing Manufacturing Process

The women’s clothing manufacturing process follows a structured, step-by-step approach that allows a women’s clothing manufacturer to transform design concepts into high-quality, market-ready garments.

Step 1: Design & Concept Development

The process begins with trend research, concept creation, and garment design. A professional women’s clothing manufacturer works closely with brands to define style, target customer, fit, and price point.

Step 2: Technical Design & Tech Pack Creation

Designs are translated into detailed tech packs that include measurements, construction details, fabric specifications, trims, and quality standards.

Step 3: Fabric & Trim Sourcing

Fabrics, linings, buttons, zippers, and labels are sourced based on design, performance, sustainability, and cost requirements. A Women’s clothing manufacturer in USA often prioritises compliant, ethically sourced materials.

Step 4: Pattern Making

Patterns are created digitally or manually to establish garment structure and ensure accurate sizing.

Step 5: Sample Development

Prototype samples are produced to test fit, construction, and aesthetics. Revisions are made until final approval is achieved.

Step 6: Fit Approval & Size Grading

Approved patterns are graded into multiple sizes to maintain consistent fit across the entire size range.

Step 7: Production Planning

Production quantities, timelines, and workflows are finalised. Materials are ordered and production schedules are confirmed.

Step 8: Fabric Cutting

Fabric is spread and cut according to graded patterns using manual or automated cutting systems to maximise efficiency and minimise waste.

Step 9: Sewing & Assembly

Garment components are assembled following approved construction methods and quality guidelines.

Step 10: Quality Control & Inspection

Finished garments undergo quality inspections to check measurements, stitching, defects, and overall finish.

Step 11: Finishing & Packaging

Garments are pressed, washed (if required), labelled, tagged, and packaged according to brand requirements.

Step 12: Shipping & Delivery

Final products are packed, documented, and shipped to warehouses, retailers, or directly to customers.

Selecting a reliable nhà sản xuất quần áo nữ goes beyond production capability. It requires alignment in values, processes, and long-term growth strategy. By choosing the right manufacturing partner, fashion brands can ensure consistent quality, efficient production, and sustainable growth in an increasingly competitive market.

Dugarco dưới sự lãnh đạo và dẫn dắt tài ba của Ông Hoàng Vệ Dũng đã từng bước trở thành nhà sản xuất quần áo lớn của Việt Nam, cung cấp quần áo cho nhiều thương hiệu nổi tiếng đến từ nhiều quốc gia khác nhau như Anh, Mỹ, Úc.